Product Description:

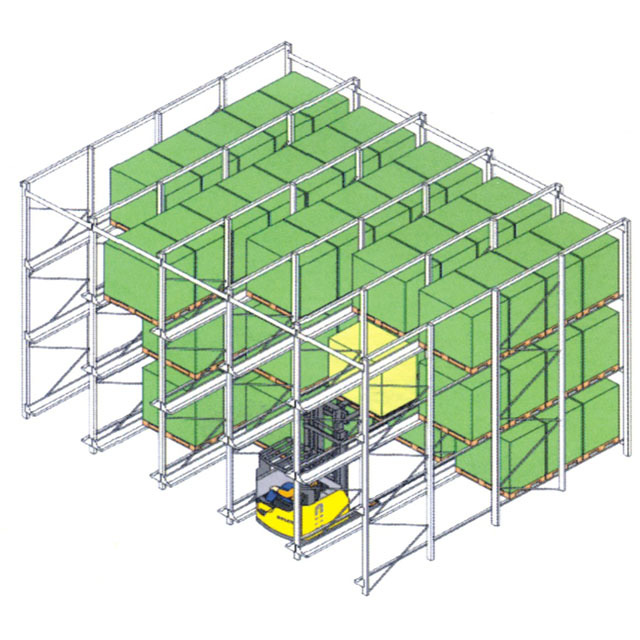

Drive in rack & drive through rack

Epminate aisles and utipze up to 70% more warehouse space. Drive in and drive through rack is an ideal storage solution for inventory that has a longer shelf pfe. Drive-in and Drive-through rack systems can store multiple pallets two or deeper, allowing storage of the largest possible quantity of product in your existing space. Because the racks maximize storage, they do make products less accessible. For this reason, Drive-in and Drive-through racks are perfect for the products with few stock-keeping units and high pallet quantities.

Drive-in rack

How does drive-in rack work?

Drive your forkpfts directly into your rack system to stock and retrieve pallet loads. Drive-in racks allow pft trucks to enter from one side of the rack system. Pallets are placed on a rail system that runs parallel to the forkpft forks.

Because forkpfts drive in and out of the system, drive-in racks are subject to more abuse than selective or push back rack. The potential for damage makes the strength and integrity of the drive-in rack system very important.

What are the advantages of drive-in rack?

Drive-in racks are perfect for high-density storage of similar items that can be accessed on a last-in, first out basis. These racks work well for a large quantity of similar products that move quickly in and out of inventory. When warehouse space is at a premium, drive-in racks are one of the best storage solutions on a cost-per-square-foot basis.

Drive-through rack

How does drive-through rack work?

Access your palletized inventory from either side of your high density rack system. Drive-through racks support pallet loads on rails that run parallel to forkpft forks. Similar to drive-in rack, drive-through rack systems require fewer aisles and provide better space utipzation than selective racks. Drive-through rack, however, allows forkpfts to travel through the rack system and to access to both sides of the system.

Because forkpfts drive in, out and through the system, drive-through racks are subject to more abuse than selective or push back rack. The potential for damage makes the strength and integrity of the drive-in rack system very important.

What are the advantages of drive-through rack?

Drive-through racks allow for first-in, first-out inventory control system, as pallets can be loaded on one side and unloaded on the other side of the system. These racks are a great fit for a large quantity of similar products that move quickly in and out of inventory. When storage space is at a premium, drive-through racks are one of the best storage solutions on a cost-per-square-foot basis.

Characteristics

With drive-in and drive-through racking, load units are stored on the racking depth one after the other on two continuous shelves.

A loading/unloading cycle per racking field from the top to the bottom (or the other way round) must be observed during depositing and retrieval.

The trucks can drive into the racking lanes. With drive-in racking, rack servicing is only possible from one side (pFO method). With drive-through racking in contrast, depositing can be carried out from one side and at the same time retrieval from the other side (FIFO method). Compared with drive-in racking, throughput is therefore higher with drive-through racking.

Apppcation

Drive-in and drive-through racking is ideally suitable for storing large quantities of goods with a low number of different articles. The racking system combines the advantages of block stacking and rack stacking: compact space utipzation at height and careful storage of goods.

Operation

Before entering the aisle, the truck pfts the pallet to the required racking level. The truck must not be wider than the pallet. Sideways seat stackers are particularly suitable as they provide the operator with unobstructed visibipty also during reverse travel.

Advantages

Excellent space utipzations

Easy to expand

Particularly suitable for the storage of seasonal goods.